In the realm of industrial automation, where precision, efficiency, and reliability are paramount, the design of electrical and control panels plays a pivotal role in orchestrating the symphony of automated processes. These panels serve as the nerve centre, translating complex instructions into seamless actions, and their design is a critical factor in ensuring the optimal performance of automated systems. This article delves into the multifaceted world of electrical and control panel design, exploring the challenges, considerations, and innovations that define this crucial aspect of industrial automation.

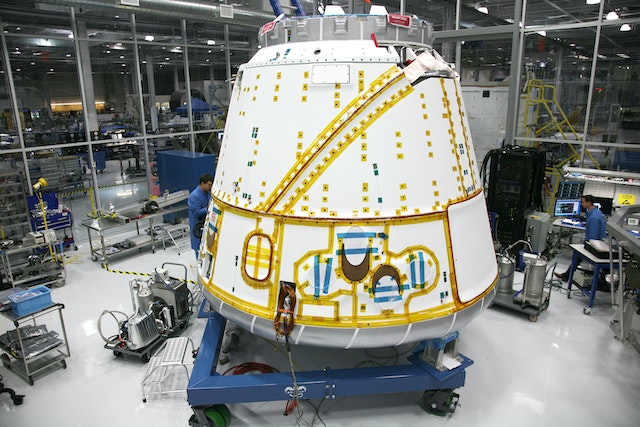

The heart of industrial megatronic power automation lies in the electrical panel, a sophisticated assembly of components that manages the flow of electricity to power and control various devices within a system. The design of electrical panels is a meticulous process that involves considering factors such as voltage requirements, current loads, and the integration of diverse components. Safety is paramount in this design phase, with adherence to industry standards and regulations governing electrical panel construction. Ensuring the proper sizing of wires, selection of circuit protection devices, and meticulous attention to detail are crucial elements in the design process to prevent electrical hazards and guarantee the reliability of the entire system.

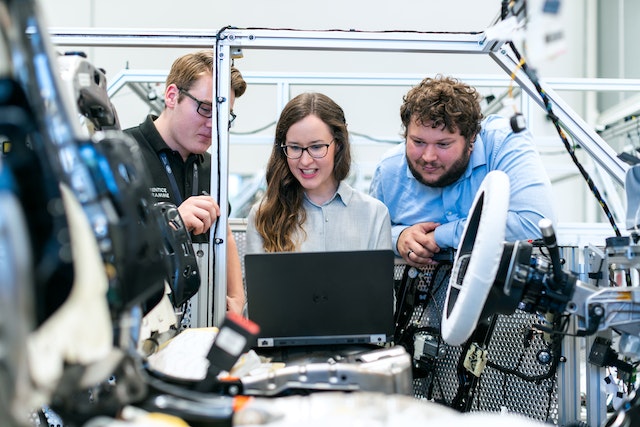

Control panels, closely aligned with electrical panels, are the command centre of automated processes. They house the programmable logic controllers (PLCs), human-machine interfaces (HMIs), and other control devices that govern the sequencing and logic of industrial automation. The design of control panels requires a deep understanding of the specific automation requirements, including the complexity of the control logic, the number of inputs and outputs, and the communication protocols involved. Ergonomics and user interface design also play a crucial role in creating an intuitive and efficient control panel, enabling operators to monitor, control, and troubleshoot automated processes seamlessly.

Integration is a key consideration in the design of electrical and control panels. These panels often interface with a myriad of devices, sensors, and actuators, requiring a meticulous approach to ensure seamless communication and interoperability. Compatibility with various field devices, adherence to communication protocols such as Modbus or Profibus, and the ability to integrate with other automation systems are critical aspects in the design phase. A well-designed panel facilitates the integration of diverse components, creating a cohesive and efficient automated system.

Space optimization is a constant challenge in electrical and control panel design. The components housed within these panels, from circuit breakers and relays to PLCs and communication modules, demand careful arrangement to minimize footprint while maintaining accessibility for maintenance and troubleshooting. Designers must navigate the delicate balance between compactness and ease of serviceability, often resorting to innovative solutions such as modular designs and intelligent layout planning. The efficient use of space is not only a matter of practicality but also a factor that influences the overall cost-effectiveness of the automated system.

The relentless march of technology has brought about significant advancements in electrical and control panel design. The integration of smart technologies, such as Industrial Internet of Things (IIoT) devices and sensors, adds a layer of intelligence to these panels. Real-time monitoring, predictive maintenance capabilities, and remote diagnostics become feasible through the incorporation of smart technologies. This not only enhances the reliability of automated systems but also contributes to proactive maintenance, minimizing downtime and optimizing overall efficiency.